El. pašto formato klaida

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

žinios

24 Kinds of Metal Materials Commonly Used in Machining and their Characteristics!(1)

Friends who work in machinery have to deal with commonly used metal materials. This time, we share 24 commonly used materials for machinery and mold processing. Do you know them?

1. 45 - high-quality carbon structural steel, which is the most commonly used medium carbon quenched and tempered steel

Main features: the most commonly used medium carbon quenched and tempered steel has good comprehensive mechanical properties, low hardenability, and is prone to cracks during water quenching. Small parts should be quenched and tempered, and large parts should be normalized. Application example: it is mainly used to manufacture moving parts with high strength, such as turbine impeller and compressor piston. Shaft, gear, rack, worm, etc. Pay attention to preheating before welding and stress relief annealing after welding.

2. Q235A (A3 steel) - the most commonly used carbon structural steel

Main features: high plasticity, toughness, weldability, cold stamping performance, a certain strength, and good cold bending performance. Application examples: widely used in parts and welded structures with general requirements. Such as tie rods, connecting rods, pins, shafts, screws, nuts, ferrules, brackets, machine bases, building structures, bridges, etc. with little force.

3. 40Cr - one of the most widely used steels, is an alloy structural steel

Main features: after quenching and tempering treatment, it has good comprehensive mechanical properties, low-temperature impact toughness, low notch sensitivity, good hardenability, high fatigue strength can be obtained when oil is cold, parts with complex shapes are easy to crack when water is cooled, medium cold bending plasticity, good machinability after tempering or quenching and tempering, but poor weldability and easy to crack. It should be preheated to 100 ~ 150 ℃ before welding, and it is generally used in the state of quenching and tempering, Carbonitriding and high-frequency surface quenching can also be carried out.

Application examples: after quenching and tempering, it is used to manufacture medium speed and medium load parts, such as machine tool gears, shafts, worms, spline shafts, thimble sleeves, etc.; after quenching and tempering and high-frequency surface quenching, it is used to manufacture parts with high surface hardness and wear resistance, such as gears, shafts, spindles, crankshafts, mandrels, sleeves, pins, connecting rods, screws, and nuts, inlet valves, etc.; after quenching and medium temperature tempering, it is used to manufacture heavy-duty and medium speed impact parts, such as oil pump rotors Sliders, gears, spindles, collars, etc. are used to manufacture heavy-duty, low impact, wear-resistant parts, such as worms, spindles, shafts, collars, etc. after quenching and low-temperature tempering. At the carbonitriding place, transmission parts with large size and high low-temperature impact toughness, such as shafts, gears, etc., are manufactured.

4. HT150 - Grey Cast Iron

Application examples: gearbox, machine bed, box, hydraulic cylinder, pump body, valve body, flywheel, cylinder head, pulley, bearing cover, etc.

5. 35 - common materials of various standard parts and fasteners

Main features: appropriate strength, good plasticity, high cold plasticity, and acceptable weldability. Local upsetting and wire drawing can be carried out in a cold state. Low hardenability, use after normalizing or quenching and tempering. Application examples: suitable for manufacturing small section parts, parts that can bear large loads: such as crankshaft, lever, connecting rod, shackle, etc., various standard parts, and fasteners.

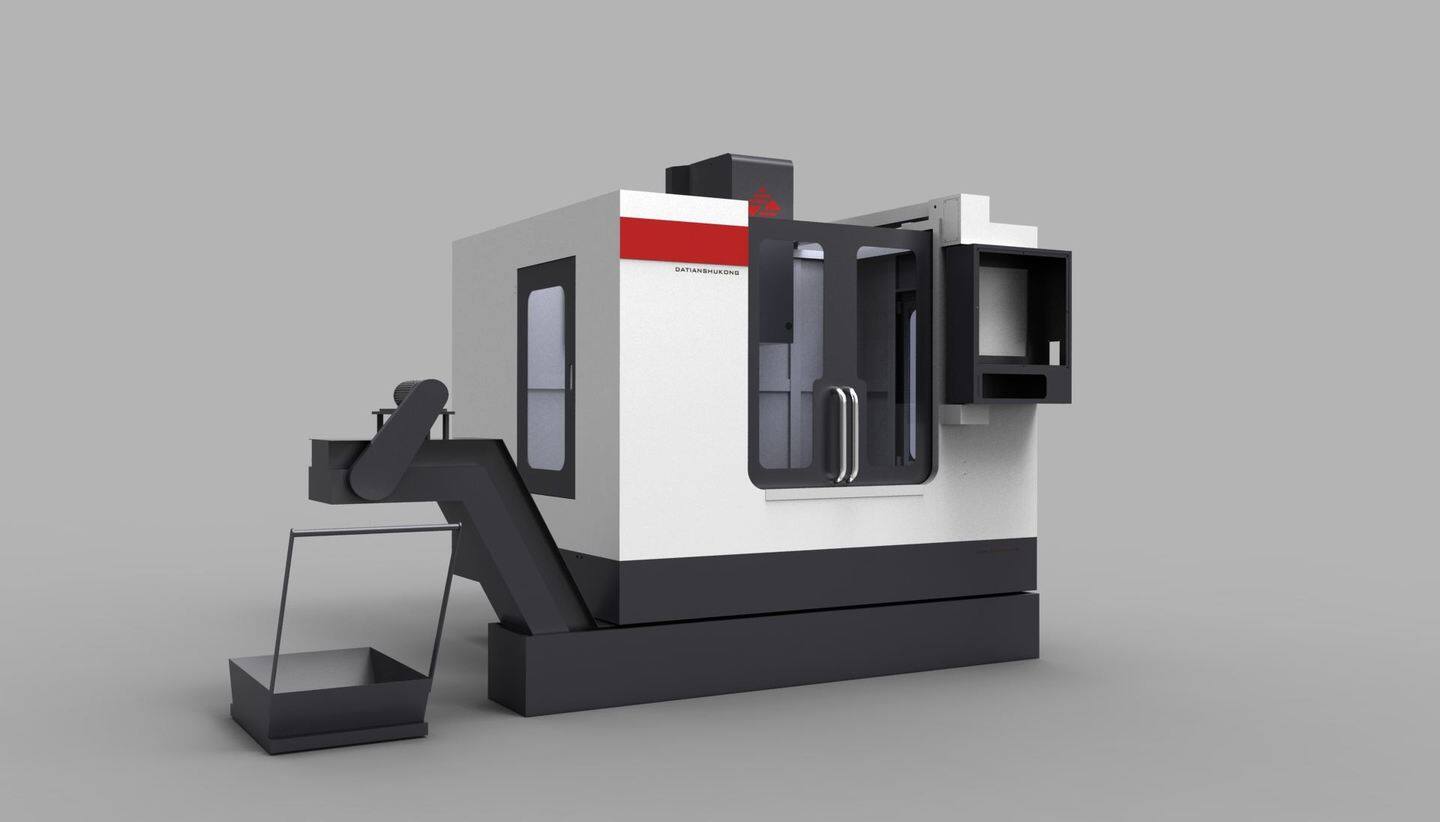

Make a purchase of 2021 desktop milling machine, 2 axis milling machine, cnc milling tool from China, you can get them at a good price if you have a large quantity. We hope to be your long-term partner.